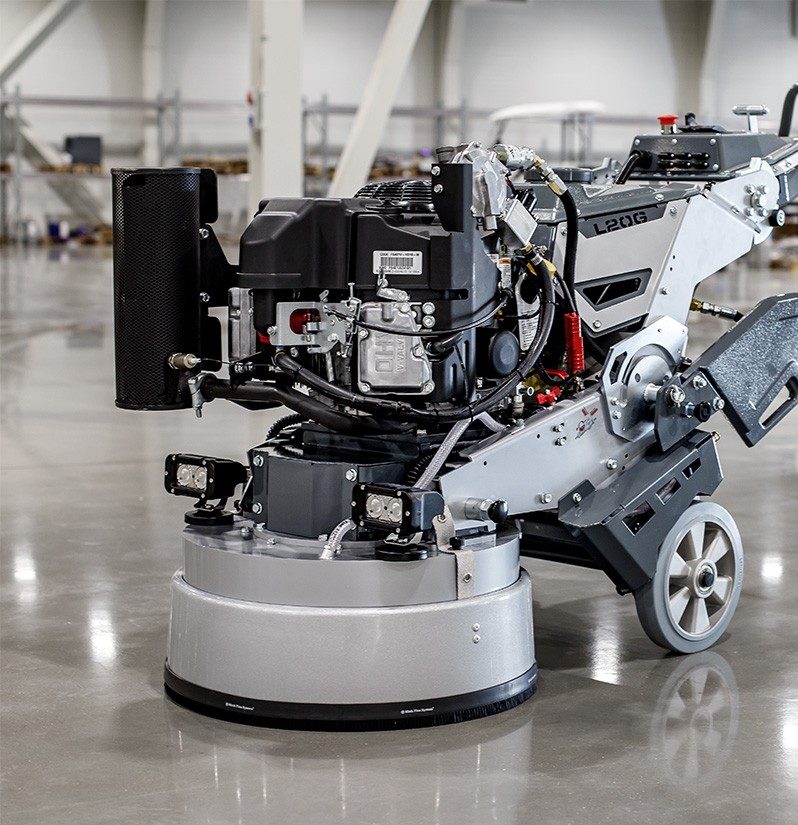

The all-new 20-inch LAVINA S7 propane grinder is combines the compact 20-inch footprint with the new S7 upgrades to deliver superior cord-free performance. The propane engine eliminates the need for power or generators on the job site, and machine set-up is a breeze.

Always use VAPOR tanks only. Do not fill over 80%, as this can cause freezing and pressure regulator damage. When propane equipment is used indoors, proper air ventilation with access to FRESH AIR and proper equipment maintenance (oil and filter changes, etc) are of critical importance for operator’s safety. Operators should always carry CO monitor or badge.

NEW SEALED & DUST-PROOF GRINDING HEAD

- Longer service life and less maintenance.

- Completely redesigned chain-driven planetary drive

- New stronger timing belt

- Upgraded shafts, seals and bearings

- New lighter timing pulleys for better power transmission

- New 2-piece aluminum main belt housing with belt inspection cover

NEW FRAME DESIGN

- Better control, easier tool changes, and less vibrations.

- New weights for faster position change

- Redesigned frame allowing easier tool changes

- Ergonomic handle design for faster adjustability and more positions

- Rubber bushing used at head attachment points for less vibrations for user

GRINDING TIPS

- Overlap around 25% of the machine work path between passes.

- Check dust skirt to make sure it is all the way down, touching the floor to reduce airborne dust. Replace skirt if worn out or damaged.

- When starting machine, hold it firmly and start moving (don’t keep it in one spot while heads are spinning).

- When stopping machine, keep moving until the grinding heads stop.

- To tilt machine up for tooling changes, move the weight back.

- To add more grinding pressure and grind more aggressively, put the weights down / forward.