Meet SP8.

Superior performance with optimal torque and speed for both flatwork and finishing operations.

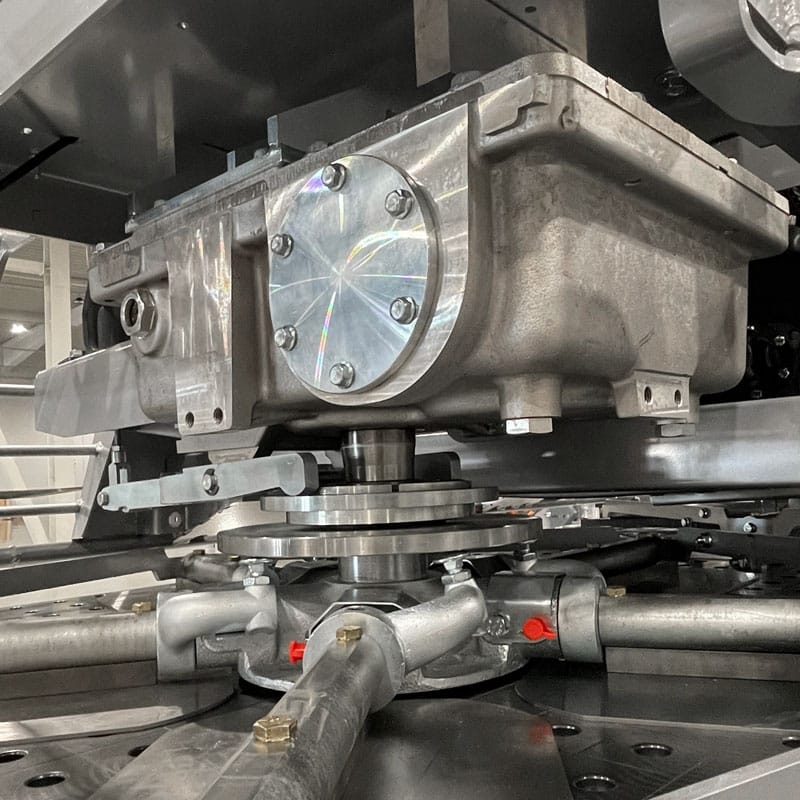

- Manual dual-lever steering with spring loaded assistant

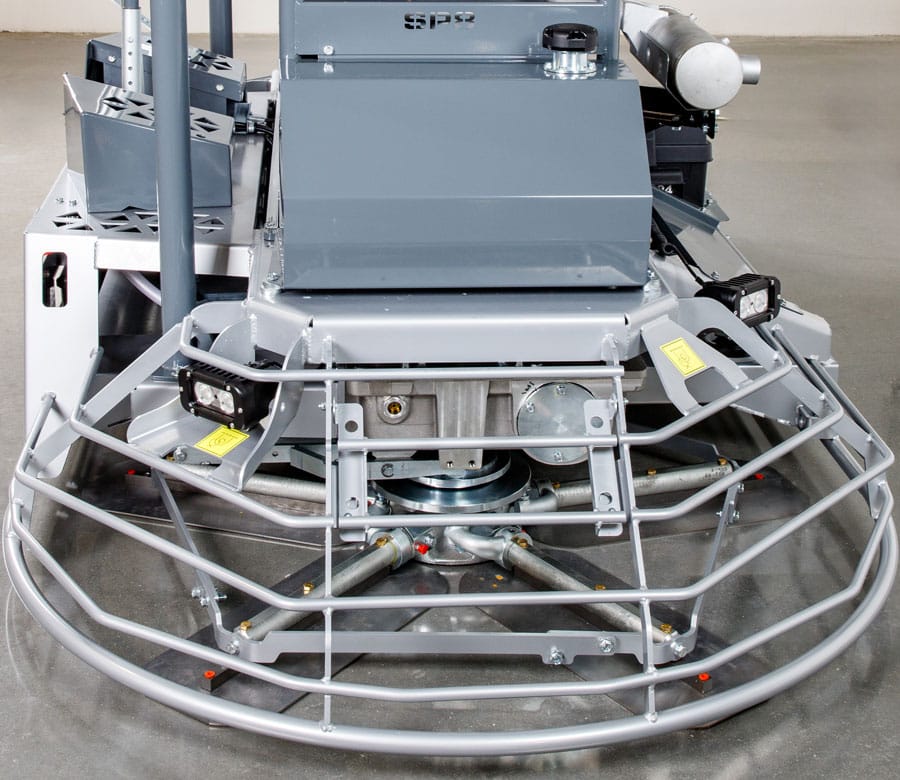

- Heavy-duty, inhouse-made helical bevel gearbox

- Heavy-duty CVT clutch

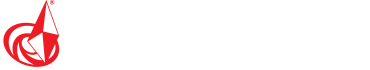

- Twin 5-blade rotors

- Integrated lift points and fork lift pockets. Lift points have stoppers to prevent straps from falling off . Shield between lift pockets to protect CVT and u-joints.

- Easy access to blades with access door with magnets – no tools needed

- Retardant spray system with 2 sprayers, controlled by buttons on the steer levers, and a drain valve

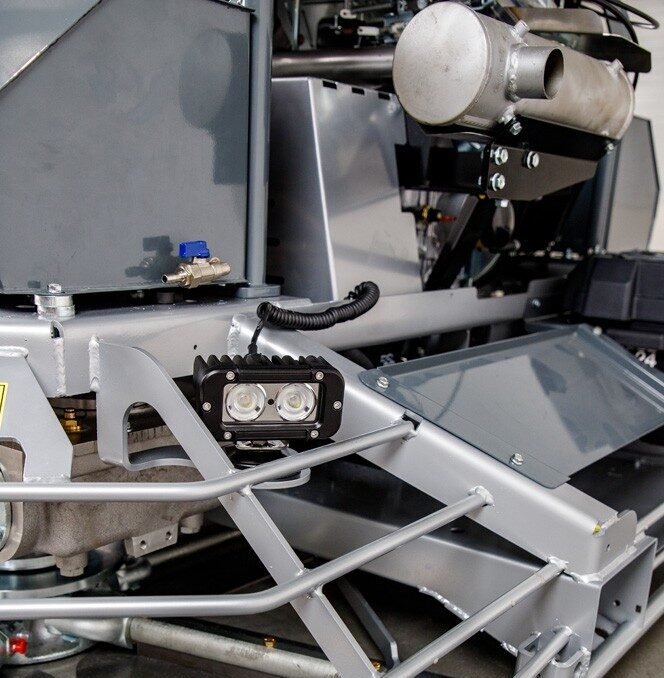

- LED lights – 3 in front, plus 2 rear lights with magnetic attachment and telescopic cable to position as needed

- Hour meter

- Led Oil indicator and Fuel level gage

- USB charger and phone holder

- Built-in cup holder

- Optional accessory – transport wheel

TROWEL BLADES AND PANS

Superabrasive now offers float pans and trowel blades, including finishing and combination blades, featuring high-quality blue steel for optimal blade life and performance. Compatible with Allen, Bartell, Champion, Dart, ESI, Essick, Kelley, MBW, Marshalltown, Morrison, Muller, Oscar, Rhin-O-Tuff , Toro / Stone, Wacker, Whiteman.

Float pans clip on to the blades of a trowel machine and are used to flatten the slab. The pans create suction and pull slurry to the surface. They also fill or cut any imperfections left from screeding and bull floating. Usually, after you pan the slab, you go back with combination blades to give it a nice shine. We offer pans in different sizes: 36″, 46″, 60″ (90cm, 120, 150mm). Available in 3 and 4mm thickness with Z-clips and Safety Rods (see data sheet for part numbers).

Combination blades are a combination of finish and float blades, featuring a floating edge on one side that allows concrete to flow under the blade, and a flat finishing edge for finishing.Finish blades are flat and have the carrier bar located in the centre of the blade. Unlike combination blades, both sides of the blade can be used, i.e the blade can be rotated 180 degrees providing a new finishing edge. Finish blades are normally used in the final stages of finishing to create a burnt finish. We offer several blades sizes (see data sheet for part numbers).