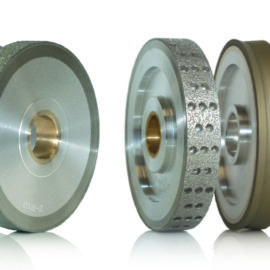

Edging Wheels

Superabrasive manufactures high quality diamond edger wheels for the most popular edging machines on the market – Nidek, Essilor, Briot, Weco, Huvitz, etc. Tell us about your machine, wheel size and types of lenses you cut, and we can offer replacement wheels at a great price. The questions below will help you determine which wheel(s) you need for your machine.

ROUGHING WHEELS

- Which edging wheel do I need for cutting?

Tell us about your machine model, wheel size and types of lenses you cut. We offer different roughing wheels for cutting polycarbonate, plastic, high-index lenses, trivex, etc. Please note if you are cutting any glass, you need a separate roughing wheel.

- Do I need a special wheel for cutting Trivex lenses?

We recommend using our TRIO roughing wheel if you cut Trivex on a regular basis (usually above 30% of all lenses). It is designed to reduce the surface temperature of both the wheel and lens for more efficient lens cutting. TRIO is also great for cutting plastic and polycarbonate lenses.

- Why does your roughing wheel for TRIVEX have holes and not slots?

Through testing, we determined that adding holes to the surface of the wheel was the most effective way of reducing its surface temperature without interfering with the rotation and axis of the lens. We found that cutting slots across the width of the wheel caused the lens to briefly lose contact with the wheel. When the wheel and the lens come back into contact, the lens experiences some jarring which creates axis problems and can ultimately damage the lens.

FINISHING AND POLISHING WHEELS

- Can I replace just the finishing wheel, or just the polishing wheel instead of both wheels?

It is recommended to replace both wheels as a matched set, so their profiles match perfectly, but you can certainly replace just one of the two, if needed.

- What is the difference between “four angled” and “flat with a V” profile?

“Four angled” finishers slope down to the V channel, while “flat with a V” wheels are completely flat from the edge of the wheel to the V channel. In most cases, you can determine which one you need by just looking at your old wheel.

- Do I need a special finishing wheel for processing TRIVEX?

The issue of overheating is only present in the roughing cycle; therefore, a special finishing wheel for processing TRIVEX is not necessary.