See catalog for a complete list of QC Metal Tools with part numbers.

Lavina QC metal tools are offered with one or two segments / buttons. We recommend using single segment tools with smaller grinders (25″ and under), and double segment tools with grinders 30″ and larger. Fewer segments cut faster, but also wear out faster. The first step to open the concrete is usually done with single button tools. More segments create more surface contact, allowing for surface refinement with less scratches.

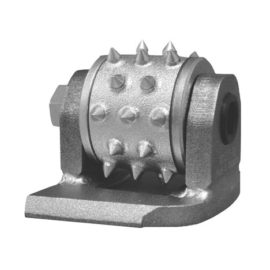

To expose medium to large aggregate, you can usually start with 30 grit metals or bush hammers for faster results. For small to medium aggregate – start with 70 grit metals. For salt and pepper – 120 grit metals.

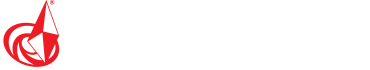

MOHS’ SCALE AND LAVINA METAL BONDS

- YELLOW SERIES for SOFT CONCRETE (under 2500 psi, Mohs Scale 2-3)

- GREY SERIES for MEDIUM CONCRETE (2500-4000 psi, Mohs Scale 3-5)

- RED SERIES for HARD CONCRETE (4000-5500 psi, Mohs Scale 5-6)

- GOLD SERIES for EXTRA HARD CONCRETE (5500-7000 psi, Mohs Scale 7)

- WHITE SERIES or BLACK CAP CUTTERS for SUPER HARD CONCRETE (7000-9000 psi, Mohs Scale 8-9)

HOW TO USE THE MOHS’ TEST KIT

A Mohs hardness test kit includes a set of pencils (or picks) with calibrated hardness values corresponding to the Mohs scale (2-9). Before starting, ensure the concrete surface is clean and free of sealers or curing compounds. The picks should be sharp and in good condition. We recommend to test in different locations to get a more accurate overall hardness value.

- Start with the pencil with the lowest hardness value (e.g., Mohs 2).

- Firmly press the tip of the pencil against the concrete surface and draw a line.

- Check if there is a scratch left behind.

- Increase the pencil hardness value (e.g., Mohs 3, 4, etc.) until you find the pencil that leaves a noticeable scratch.

- The Mohs hardness value of the last pencil that leaves a scratch is the approximate hardness of the concrete. The higher the Mohs hardness value, the harder the concrete.

- This test is not precise but provides a general idea of the concrete’s hardness, which can help guide the selection of appropriate tools and materials for concrete polishing and grinding.

- Our QC tools come with a reference guide showing the recommended bond for different Mohs’ hardness.

GRINDING TIPS:

- SOFT CONCRETE is very abrasive and wears out the bond and diamonds faster. You should use a hard bond, such as the QC Yellow series for optimal efficiency. If you use our QC Red, Gold or other soft bonds, they will cut fast but will wear out fast as well.

- HARD CONCRETE requires a soft bond tool, such as the Lavina Red, Gold, White or Black tools. The QC Yellow or Grey tools might glaze. Glazed diamonds slide on the concrete surface without cutting because there is not enough abrasion to keep them open. To unglaze and open the diamonds, you can try removing weights, slowing rpms, adding water (mist) or silica sand (30 grit). If glazing continues, you should switch to a softer bond.

- We recommend using metals with LOW RPM.

- Use QC tooling with Security Plates for safe operation.