TROWEL FEATURES:

Engineered for maximum productivity and performance

-

Propane-driven ride-on trowel with a free planetary drive – built specifically for concrete polishing.

-

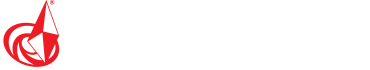

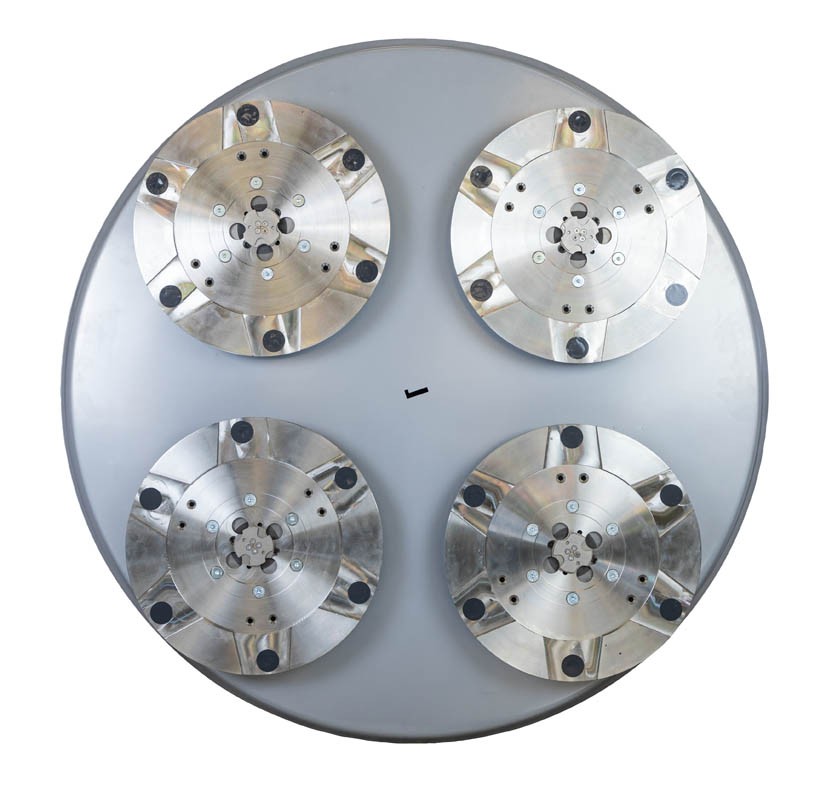

Equipped with two 36-inch floating pans, and each pan has four 13.2″ Tools Holders with quick change attachment – uses the same Lavina tooling, as your grinders. You can run metal tooling and it will not slow down or bog down…most others can not.

- Powerful KOHLER Propane engine – cleaner, more fuel efficient, more uptime and better warranty.

- Sealed undercarriage to help with slurry damage….other trowels have to be greased constantly and cleaned very well.

- Continuously variable transmission provides superior performance by continually adjusting the drive ratio to obtain optimum torque and speed during all phases of finishing from low-speed, high-torque to high-speed burnishing.

- Easy to maneuver and control.

- Transportation system and internal jack to allow quick tool changes and loading.

- Heavy-duty shroud with pins to protect walls from slurry.

- Integrated wheel set and manual crank system to lift the trowel (200mm) for changing tools. Transportation wheel included as well.

- LED lights for better visibility.

- Emergency stop sensor on the operator’s seat.

DIAMOND TOOLING FOR LAVINA POLISHING POWER TROWELS:

- If grinding is necessary (rain drop or damaged concrete), start with Quick Change SA Superthick Metals. Don’t forget to use QC Security Plates to lock the Quick Change tooling in place (A64.00.01 for metals and A84.00.00 for 13″ rings).

- Follow with Coppers 50 or 100 grit to remove scratches and transition to resins. On flat floors you can start with Waffel Resin Pads 50 grit or 120 grit in the wet bond.

- Continue with Waffel Resin Rings 220 grit.

- Densify after 220 grit.

- Follow with Waffel 400 or Nato 400 grit.

- After 400 grit, you can switch to V-Harr Polishing Rings or SupraShine Pads and continue up to the desired gloss level.

- We also offer SupraShine pads in 36″ and 48″ size that can be attached directly to the pans with velcro strips. Start with SupraShine HD 220 and 400 grit, and continue with SupraShine HP 800, 1800, 3500.

See the trowel in action: