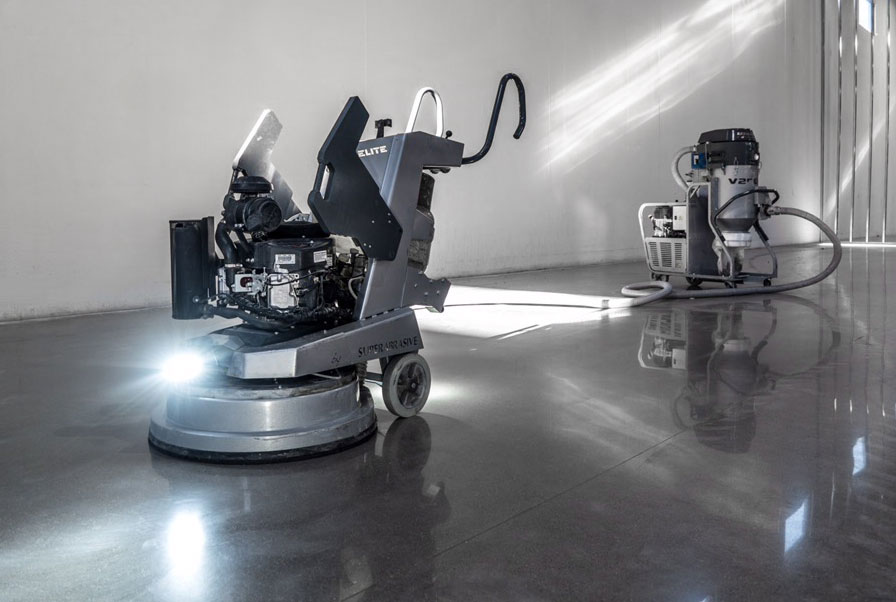

L30GEB is a very powerful grinding and polishing machine that contractors love for its ease of use, productivity and versatility. From prepping garage floors for epoxy to polishing large warehouses, the L30GEB grinder delivers performance above the rest.

Always use VAPOR tanks only, and do not fill over 80%, as this can cause freezing and pressure regulator damage. When propane equipment is used indoors, proper air ventilation with access to FRESH AIR and proper equipment maintenance (oil and filter changes, etc) are of critical importance for operator’s safety. Operators should always carry CO monitor or badge.

GRINDER FEATURES

- IMPROVED WATER SYSTEM with gravity-fed water supply from the water tank and hose connection delivers more water under the machine for optimal wet grinding and simpler maintenance. There is no water pump or misting system on the new machines.

- REAR WHEEL SET – this new feature makes grinder transportation and loading easier. It comes installed on all 20/25/30-inch Elite machines, and it is also available as an accessory for previous Elite models.

- OPTIONAL 3RD WHEEL (available for propane only 25/30-inch Elite machines) & OPTIONAL LEVER FOR LIFTING THE MACHINE UP (available for all 25/30-inch Elite machines).

- Completely redesigned frame delivers superior maneuverability and easy tool changes.

- Dust-proof planetary drive protects internal components from dust and moisture, which reduces maintenance and increases service life.

- The heads of all propane grinders have counter-clockwise / LEFT rotation. Use the Blue PCDs and Carbide Scrapers.

- Easy-to-use integrated weights.

- Improved dust collection efficiency. Adjustable skirt with a flexible brush for better dust containment. Also, vacuum hose connection a metal camlock close to the head.

- EPA & CARB Blue Sky Engine – our certified engine kit provides optimal performance with more uptime and lower emissions.

- Adjustable handle bar with multiple handle positions for more convenient operation and transportation.

- LED lights for monitoring the floor.

- Convenient integrated lift points for moving the machine with a forklift.

- Charging phone station.

- Durable stainless steel cup holder.

GRINDING TIPS

- Overlap around 25% of the machine work path between passes.

- Check dust skirt to make sure it is all the way down, touching the floor to reduce airborne dust. Replace skirt if worn out or damaged.

- When starting machine hold it firmly and start moving (don’t keep it in one spot while heads are spinning).

- When stopping machine, keep moving until the grinding heads stop.

- To tilt machine up for tooling changes, move the weights back.

- To add more grinding pressure and grind more aggressively, put the weights down / forward.

- Always lock the weights during transportation.

photo credit: Creted LLC